The ZF 6HP21 is a 6-speed automatic transmission designed for rear-wheel-drive vehicles‚ known for its electronic control and efficient performance. It features advanced components like the EDS3 solenoid‚ which plays a critical role in gear shifting and pressure regulation. Understanding the EDS3 solenoid diagram and manual is essential for troubleshooting‚ maintenance‚ and repair‚ ensuring optimal transmission functionality and longevity.

1.1 Overview of the ZF 6HP21 Transmission

The ZF 6HP21 is a 6-speed automatic transmission produced from 2006 to 2007‚ designed for rear-wheel-drive vehicles. It is an upgraded version of the 6HP19‚ offering enhanced performance and compatibility with engines up to 3.0 liters. This transmission features electronic control‚ a mechatronic unit‚ and a torque converter for smooth operation. Its gear ratios and planetary design ensure efficient power delivery. The EDS3 solenoid is a key component‚ regulating pressure and gear shifts. Understanding its structure and operation‚ as detailed in the solenoid diagram and manual‚ is crucial for maintenance and repair.

1.2 Importance of the EDS3 Solenoid Diagram and Manual

The EDS3 solenoid diagram and manual are vital for diagnosing and repairing issues in the ZF 6HP21 transmission. The diagram provides a detailed layout of the solenoid’s electrical connections and hydraulic circuits‚ enabling precise troubleshooting. The manual offers step-by-step repair instructions and specifications‚ ensuring accurate replacement and maintenance. These resources are essential for technicians to resolve common problems like erratic shifting or limp mode‚ caused by solenoid malfunctions. Together‚ they help maintain optimal transmission performance and prevent costly damages.

Key Components of the ZF 6HP21 Transmission

The ZF 6HP21 transmission features the EDS3 solenoid‚ mechatronic unit‚ and torque converter as its primary components. These parts ensure smooth gear shifts‚ electronic control‚ and efficient power transfer.

2.1 EDS3 Solenoid Function and Role

The EDS3 solenoid is a critical component of the ZF 6HP21 transmission‚ responsible for regulating hydraulic pressure through pulse-width modulation (PWM). It ensures smooth gear shifts by controlling clutch and band engagement. The solenoid directly impacts transmission performance‚ enabling precise control over torque converter lock-up and gear transitions. Proper functioning of the EDS3 solenoid is essential for maintaining optimal transmission operation‚ and its failure can lead to erratic shifting and reduced performance. The solenoid diagram in the PDF manual provides detailed insights into its circuitry and operation.

2.2 Mechatronic Unit and Its Integration

The Mechatronic Unit in the ZF 6HP21 transmission integrates electronic control with hydraulic functionality‚ serving as the brain of the system. It processes data from sensors and adjusts solenoid operations like the EDS3 to optimize shifting. The unit’s advanced programming ensures smooth gear transitions and adaptive learning for driver behavior. Its integration with the solenoid system is detailed in the PDF manual‚ highlighting how it interprets signals and executes commands. This seamless integration is vital for the transmission’s overall efficiency and responsiveness‚ making it a cornerstone of modern automatic transmissions.

2.3 Torque Converter and Its Significance

The torque converter in the ZF 6HP21 transmission is essential for smooth power transfer between the engine and transmission. It features an electronic lock-up clutch that engages from first gear‚ enhancing fuel efficiency and reducing slip. The converter’s design allows it to adapt to various driving conditions‚ ensuring optimal torque multiplication during acceleration. Proper installation and alignment‚ as outlined in the manual‚ are critical for maintaining transmission performance and preventing damage. The torque converter’s integration with the mechatronic unit ensures precise control‚ making it a vital component for seamless gear transitions and overall transmission reliability.

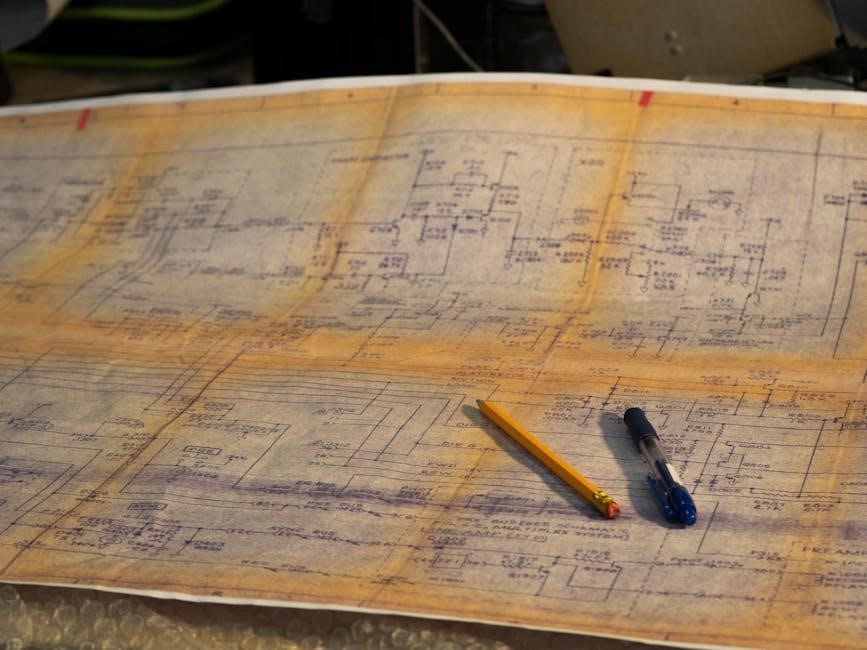

Understanding the EDS3 Solenoid Diagram

The EDS3 solenoid diagram provides a detailed visual representation of the solenoid’s electrical connections and hydraulic circuits‚ essential for diagnosing and repairing transmission issues. Referencing the PDF manual ensures accurate troubleshooting and maintenance‚ as it outlines proper solenoid operation and integration within the ZF 6HP21 system.

3.1 Structure and Layout of the Solenoid Diagram

The EDS3 solenoid diagram is structured to clearly illustrate the electrical and hydraulic connections of the solenoid. It typically includes a detailed layout of the solenoid’s internal components‚ such as the coil‚ valve body‚ and pressure-regulating circuits. The diagram is often color-coded to differentiate between various hydraulic lines and electrical wires‚ making it easier to identify and trace connections. The PDF manual accompanying the diagram provides labels and explanations for each part‚ ensuring a comprehensive understanding of the solenoid’s operation and integration within the ZF 6HP21 transmission system.

3.2 Interpreting the PDF Manual for Solenoid Repair

The PDF manual provides detailed instructions for diagnosing and repairing the EDS3 solenoid. It includes step-by-step procedures for testing solenoid resistance‚ checking electrical connections‚ and replacing faulty components. The manual also offers troubleshooting guides‚ error code interpretations‚ and repair procedures specific to common solenoid-related issues. By referencing the solenoid diagram‚ users can identify and apply the correct repair methods. The manual emphasizes proper tools and safety precautions‚ ensuring a systematic approach to resolving solenoid malfunctions and restoring transmission performance effectively. This resource is indispensable for technicians and DIY enthusiasts alike.

Solenoid Replacement and Maintenance

Replacing the EDS3 solenoid requires consulting the PDF manual for precise steps. Regular maintenance‚ such as cleaning connections and checking resistance‚ ensures optimal performance and prevents future issues.

4.1 Step-by-Step Guide to Replacing the EDS3 Solenoid

Replacing the EDS3 solenoid involves removing the transmission pan and filter. Drain the ATF and refill with G 060 162 A fluid. Start the engine‚ release the parking brake‚ and cycle through gears to prime the system. Ensure proper alignment and torque specifications when reinstalling components. Dispose of the old solenoid and fluid responsibly. Refer to the PDF manual for detailed diagrams and procedures to avoid errors during installation. Proper sequencing ensures smooth transmission operation post-replacement.

4.2 Maintenance Tips for Prolonging Solenoid Life

Regular ATF changes with G 060 162 A fluid and filter replacements are crucial for solenoid longevity. Avoid extreme driving conditions that strain the transmission. Ensure proper fluid levels and monitor for symptoms like erratic shifting or warning lights. Clean the transmission pan and solenoid area during servicing to prevent debris buildup. Refer to the PDF manual for specific maintenance intervals and procedures. Addressing issues early prevents premature solenoid failure and ensures smooth transmission operation.

Troubleshooting Common Issues

Common issues include slipping‚ delayed shifting‚ or limp mode. Check for faulty solenoids‚ low ATF levels‚ or clogged filters. Scan for error codes using diagnostic tools to identify root causes and guide repairs effectively.

5.1 Identifying Symptoms of a Faulty Solenoid

Common symptoms of a faulty EDS3 solenoid include erratic shifting‚ slipping‚ or delayed gear engagement. The transmission may enter limp mode‚ especially under heavy acceleration‚ triggering an “e-clutch” fault. Drivers might notice jerking or hesitation between gears. Dashboard warning lights often illuminate‚ indicating electronic control issues. These symptoms can lead to reduced performance and potential damage if left unaddressed. Consulting the solenoid diagram and manual is crucial for accurate diagnosis and repair‚ ensuring proper functionality and preventing further complications.

5.2 Diagnostic Procedures for Solenoid-Related Problems

Diagnosing solenoid-related issues in the ZF 6HP21 involves checking for fault codes using a scan tool. Common codes include those related to solenoid circuit malfunctions. Technicians should test solenoid resistance and ensure proper electrical connections. Visual inspections for worn or damaged components are also essential. Road testing can reveal symptoms like slipping or erratic shifting. Referencing the EDS3 solenoid diagram in the manual helps pinpoint faulty circuits. Accurate diagnosis is critical to prevent further transmission damage and ensure reliable repairs.

Transmission Fluid and Filter

The ZF 6HP21 requires green transmission fluid (G 060 162 A) for optimal performance. Regular fluid changes and filter replacements (part number 702J) are crucial for maintaining transmission health.

6.1 Importance of Proper Transmission Fluid Levels

Maintaining correct transmission fluid levels is critical for the ZF 6HP21’s performance. The fluid lubricates components‚ prevents overheating‚ and ensures smooth gear engagement. Low levels can cause friction‚ wear‚ and potential damage to clutches and bands. Overfilling can lead to leaks and reduced efficiency. Use the specified green ATF (G 060 162 A) and refer to the manual for the 9-liter capacity. Regular checks and top-ups are essential‚ especially after fluid changes or repairs‚ to prevent solenoid malfunctions and ensure optimal transmission operation.

6.2 Guidelines for Replacing the Transmission Filter

Replacing the transmission filter in the ZF 6HP21 is essential for maintaining fluid cleanliness and transmission health. Use the specified filter (part number 450J)‚ which includes the oil pan‚ gasket‚ and filter assembly. Drain the old fluid before removing the filter to minimize spillage. Inspect the pan for debris and install the new filter securely. Refill with the recommended green ATF (G 060 162 A) to the correct level; Proper disposal of used fluid and filters is environmentally responsible. Always refer to the manual for torque specifications and procedures.

The Role of the Mechatronic Unit

The mechatronic unit integrates the valve body and electronic control‚ managing hydraulic pressure and solenoid activation for precise gear shifts and optimal transmission performance in the ZF 6HP21.

7.1 Overview of the Mechatronic Unit’s Function

The mechatronic unit in the ZF 6HP21 transmission serves as the central control system‚ integrating electronic and hydraulic components. It manages gear shifts by controlling solenoids like the EDS3‚ regulating hydraulic pressure‚ and monitoring transmission performance. This unit ensures smooth and precise gear transitions by processing data from various sensors and executing commands accordingly. Proper functioning of the mechatronic unit is crucial for the transmission’s efficiency and reliability‚ making it a key component in maintaining optimal vehicle performance.

7.2 How to Program and Code the Mechatronic Unit

Programming and coding the mechatronic unit in the ZF 6HP21 transmission require specialized tools and software. Connect the transmission control module to a compatible diagnostic tool‚ ensuring the vehicle is in a stationary position. Select the appropriate model and transmission type in the software interface. Upload the latest firmware and calibration data‚ following the manufacturer’s instructions. After programming‚ test the transmission by cycling through gears to verify proper operation. Always refer to the repair manual for specific coding procedures to avoid errors and ensure compatibility with your vehicle’s system.

Transmission Rebuild and Overhaul

A transmission rebuild involves disassembling‚ inspecting‚ and replacing worn components. Use the EDS3 solenoid diagram to identify critical parts‚ ensuring precise reassembly. Follow the manual’s guidelines for torque specifications and lubrication. Replace seals‚ gaskets‚ and clutch packs as needed. Refill with the recommended transmission fluid‚ and test the system post-rebuild to ensure smooth operation and prevent future issues. Proper tools and a clean workspace are essential for a successful overhaul.

8.1 Essential Tools and Resources for a Transmission Rebuild

Rebuilding the ZF 6HP21 requires specialized tools‚ such as a deep socket set‚ torque wrench‚ and a dial indicator for precise measurements. A transmission fluid pump and filter wrench are also necessary. The EDS3 solenoid diagram and repair manual are critical for understanding circuit connections and troubleshooting. Additionally‚ a set of MK tools‚ like the MK19 for mechatronic unit disassembly‚ is highly recommended. Ensure access to genuine ZF parts‚ such as seals‚ gaskets‚ and clutch packs‚ to maintain reliability. Proper resources‚ including the exploded parts list from the manual‚ will guide accurate reassembly and component replacement;

8.2 Key Components to Inspect During an Overhaul

Detailed inspection of the ZF 6HP21 involves checking the torque converter for proper alignment and wear. Clutch packs‚ bearings‚ and planetary gears must be examined for damage or excessive wear. The mechatronic unit and EDS3 solenoid should be tested for electrical functionality. Seals and gaskets are crucial for preventing fluid leaks‚ and the valve body must be cleaned and inspected for debris. Using the repair manual ensures all components are assessed and replaced as needed‚ ensuring a reliable rebuild and optimal transmission performance.

Resources and References

Repair manuals‚ PDF guides‚ and part catalogs for the ZF 6HP21 are available through authorized dealers‚ online marketplaces like eBay‚ and specialized transmission forums.

9.1 Where to Find the ZF 6HP21 Repair Manual

The ZF 6HP21 repair manual can be sourced from authorized ZF dealers‚ repair shops‚ or online platforms like eBay and Amazon. Digital versions‚ including PDF files‚ are available for download‚ offering detailed diagrams and instructions for solenoid repairs‚ transmission overhauls‚ and maintenance. Additionally‚ specialized forums and communities often share resources‚ part lists‚ and guides‚ making it easier to locate specific information for the EDS3 solenoid and other critical components.

9.2 Recommended Online Forums and Communities

Online forums and communities like Reddit’s DIY and automotive groups‚ BMW enthusiast forums‚ and transmission-specific forums are invaluable resources for ZF 6HP21 information. These platforms offer detailed discussions‚ shared repair guides‚ and expert advice. Members often provide links to diagrams‚ troubleshooting tips‚ and repair manuals. Participating in these communities can help you connect with experienced technicians and enthusiasts‚ ensuring you have access to reliable information and support for maintaining or repairing your transmission.